In industrial equipment operation and maintenance management, the timely and correct replacement of wearable parts (such as bearings, seals, filter elements, etc.) is a core link to ensure stable equipment operation. However, traditional replacement manuals rely on textual descriptions, 2D drawings, or on-site training, which have problems such as vague operation steps and omission of technical key points, leading to low replacement efficiency, high error rates, and even equipment failures. Wearable parts replacement animation, as a 3D visualization tool, transforms complex replacement steps into intuitive visual language through dynamic simulation, interactive demonstration, and standardized process decomposition, becoming a key technical support for improving equipment reliability. This article will analyze the core role of wearable parts replacement animation in industrial operations from the perspectives of technical principles, application scenarios, and implementation value.

I. Technical Principles: Reconstructing Replacement Processes with 3D Visualization

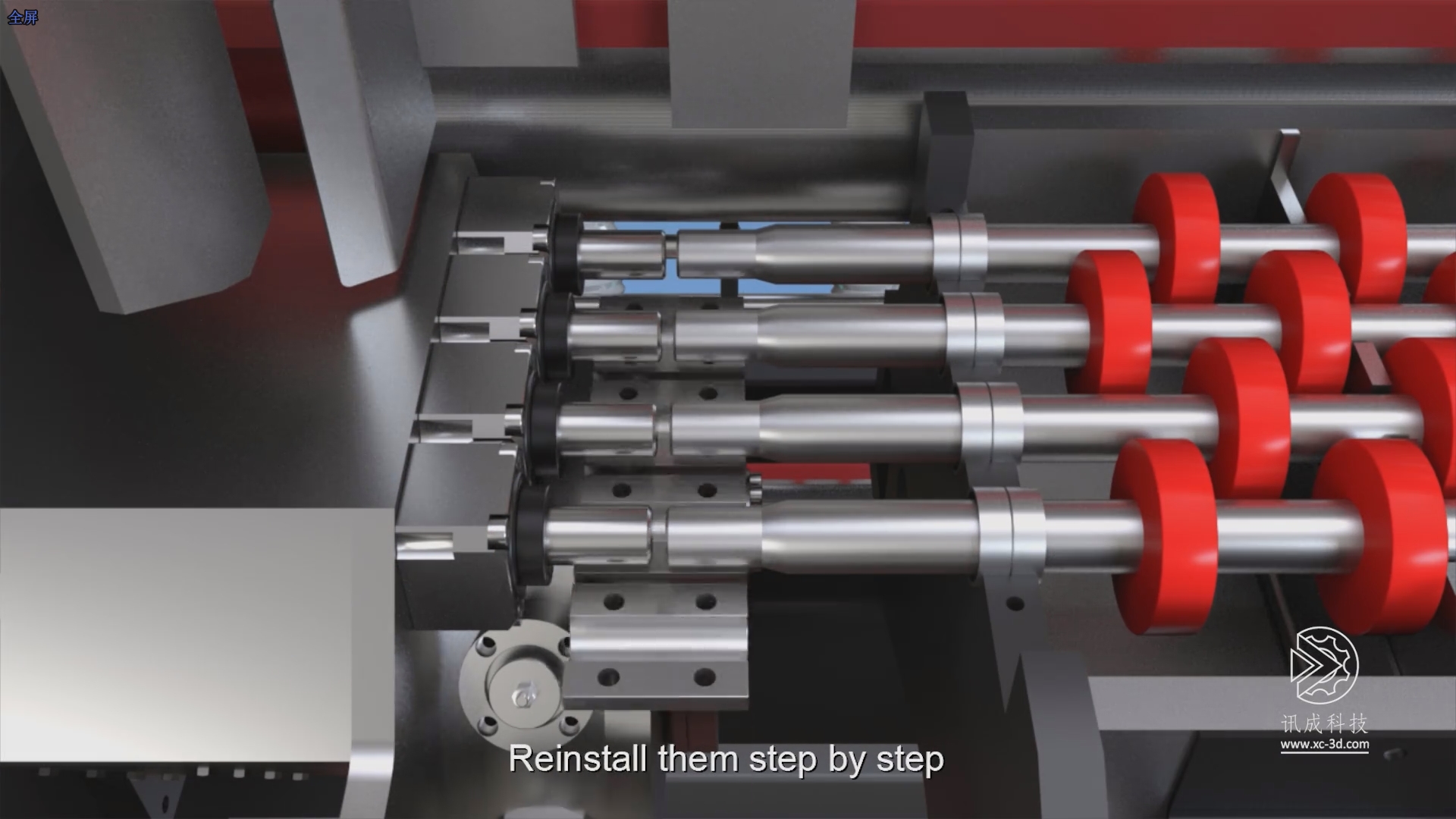

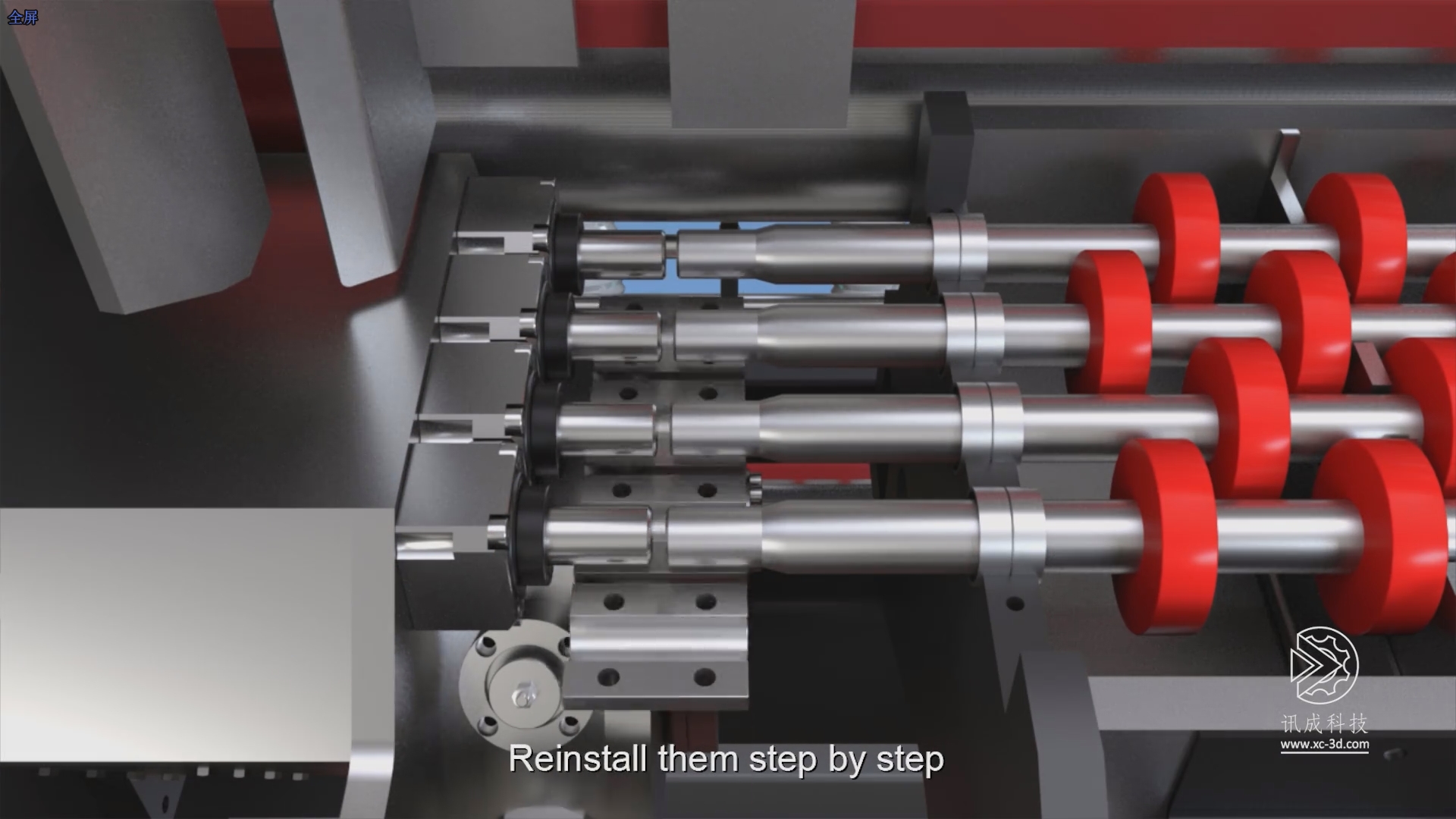

Dynamic Simulation Decomposes Replacement StepsGuangdong Tuopin Intelligent Machinery Technology Co., Ltd. commissioned Xiamen Xuncheng to produce animation videos to demonstrate the production processes of the entire machine's operation, maintenance, repair, wearable parts replacement, and safety. It not only restores the equipment operation and maintenance processes but also shows the location of wearable parts and decomposes the replacement process into standardized steps through dynamic demonstration.

Interactive Design Enhances Operational AccuracyXiamen Xuncheng integrates software technology to design the entire equipment operation and maintenance animation into interactive scenarios. Tuopin Intelligent embeds the interactive tablet iPad on the machine equipment's console for easy learning and application by operators.

For cross-border equipment, the interactive tablet iPad supports multi-language subtitles, voice, and interface, eliminating language barriers.

II. Application Scenarios: Covering the Full Operation and Maintenance Cycle

In the standardized training of technical personnel, wearable parts replacement animation can serve as standardized training material, replacing the limitations of traditional "learning by doing on-site." For emergency fault rapid response, in case of sudden wearable parts failure, animation videos can also provide on-site guidance support, helping customers complete wearable parts replacement independently.

III. Implementation Value: Quantifying O&M Efficiency Improvement

Traditional wearable parts replacement relies on on-site engineer guidance, leading to labor occupation and communication errors. Through animation training, learning and application become intuitive, reducing labor and time costs. Furthermore, animation content reinforces standardized replacement steps, avoids human oversights, and improves equipment reliability. By demonstrating the cycle of wearable parts replacement and maintenance requirements through animation, companies can also optimize equipment maintenance plans and extend equipment service life.

Wearable parts replacement animation, through 3D visualization, interactive learning, and remote collaboration, solves the pain points of traditional replacement guidance being "abstract and difficult to understand," "expensive," and "lagging in response," becoming a "reliability accelerator" for industrial equipment operation and maintenance. Enterprises can deploy wearable parts replacement animations to build a "standardized training - rapid response - independent maintenance" full-chain operation and maintenance management system, achieving the dual goals of improving equipment reliability and controlling O&M costs.

FAQ Highlights:

Q: How to produce 3D animations related to equipment maintenance?

A: Most mechanical factories and production plants rely on experienced and qualified electromechanical engineers for equipment maintenance. Equipment maintenance animations can effectively solve this problem.

1- It is recommended to first produce animations for common equipment failure points (including mechanical and electrical);

2- Record and document on-site maintenance to accumulate material for animation production;

3- Quantity: It is recommended to produce about 10-15 mechanical maintenance animations and 5-8 electrical maintenance animations for large equipment; about 6-8 mechanical maintenance animations and 3-5 electrical maintenance animations for small and medium-sized equipment;

4- Equipment maintenance animation is a process of continuous accumulation and optimization, with a relatively long production cycle, and project对接 personnel should be relatively stable.

Q: How to avoid exposing sensitive equipment structures in animation videos?

A: Some customers worry about animation videos exposing sensitive parts of their products. The following methods can be used to resolve this:

1- When the customer provides product or equipment models, sensitive structures can be deleted or deformed. (Model simplification and occlusion, blurring and fogging, color adjustment and fusion)

2- The animation camera design should not display the structure of sensitive parts, but present them in an symbolic way.

3- The animation video can be divided into a complete version and a sales version. The sales version does not contain sensitive parts and can be distributed externally; the complete version is not distributed externally and is shown when explaining to customers.

Q: Are animation videos expensive?

A: The price of animation videos varies greatly, mainly depending on the production difficulty, duration, creative style, production cycle, and service content. On the surface, animation videos are not cheap, with prices mostly ranging from tens of thousands to hundreds of thousands of yuan. However, for high-end promotional videos of industrial products and machinery and equipment, animation videos are very cost-effective.

1- Replaces traditional paper brochures, is intuitive and easy to understand, spreads quickly, and reduces reliance on experienced salespeople.

2- Animation videos have high quality, perfectly showcasing many details and unique functions and structures, making communication with customers more in-depth.

3- Animation videos can be made interactive, increasing customer engagement.

About Xuncheng Technology

Founded in 2016, with 9 years of professional industrial 3D animation creation experience, serving clients ranging from startup teams, overseas clients, listed companies, and foreign-funded enterprises. We specialize in providing 3D animation creation services for mechanical equipment, high-tech industries, software development, foreign trade companies, etc. From product sales to after-sales maintenance, we offer one-stop industrial 3D animation creative services.

We have provided nearly 3000 minutes of professional animation videos for over 200 manufacturing enterprises.

Whether at exhibition sites or visiting clients; whether expanding overseas markets or improving after-sales service, we firmly believe that through the power of design, complex products and machinery and equipment can be presented in stunning 3D animations. This not only brings a unique visual experience to customers but also quickly resonates with them.